Float type high precision belt scale

Electronic belt scale as a bulk material weighing equipment widely used in electric power, coal, metallurgy, chemicals, ports, building materials and other industries. Saimo as China's largest belt scale manufacturers, belt weigher national standards drafts the drafters, leveraging China's market demand, the urgency of urgency, in recent years, continuous innovation have introduced six new technologies, the belt scale in the use of precision, stability Reliability, the convenience of material calibration has been greatly improved, the level of the world's leading belt scale technology.

Saimo high-precision stability belt scale main features:

1. Sai Mo position difference stability technology, real-time monitoring of the belt changes in state, to maintain long-term stability of the belt scale accuracy.

2. Using Saimo multi-point flow compensation technology to ensure that the flow of different materials can be met under the high-precision measurement.

3. Using Saimo three weighing technology, real-time monitoring of load cell abnormalities, timely switching fault load cell to ensure continuous weighing.

4. Using Saimo floating balance weighing bridge, breaking the traditional design concept, infinite-bit structure, double-load cell direct force transmission, high accuracy.

5. Sampling the scene digital converter, the scale in the field of analog-digital conversion of the signal digital Far EasTone, to ensure high-precision signal transmission.

6. Optional Saimo remote diagnosis box, the use of wireless networks using large data technology to achieve belt scale remote monitoring, diagnosis, maintenance, to provide customers with the most professional belt scale adjustment advice and guidance.

In the continuous introduction of new technology, based on the belt scale, Saimo Electric through long-term research and a large number of tests, invented the latest belt scale error theory - based on position difference theory of high-precision dimensional stability technology; Electronic Belt scale.

Position difference theory:

Saimo study found that the locations of the two sets of belt scales due to the installation point of the belt tension lead to the same material weight through the two sets of belt scales to detect the weight of different materials, A group of scale frame force greater than N Group balance frame force, position difference = AN

Further research found that the location of the A to N out of the size of the difference between the size of A to N between the belt hardness and tension of the state, this state changes in the long-term stability of the belt scale is the Main factor.

Based ON at The position Difference Theory, by Detecting at The position Difference the BETWEEN at The Belt Scale and at The Normal the running Time, at The Deviation error IS Obtained. This Deviation Reflects at The Softness and the TENSION of at The Belt Changes. Which CAN Help to Deviate from at The error Correction Belt Scale Calibrated the Range Calibration Number, at The use of at The REVISED the Range Calibration Number for Weighing, to the compensate at The Belt Hardness and the TENSION Changes ON at The Weighing Accuracy of at The Impact, to of Ensure at The Long-Term Stability of at The Belt Scale. Well-known_y Experts in The weighing technology evaluation for the "belt scale long-term stability of the major breakthroughs in technology."

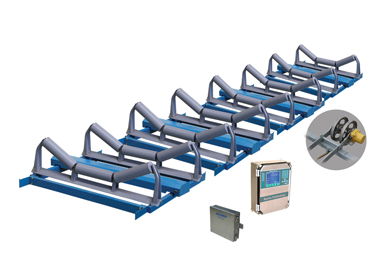

Saimo FH-16 16-roller high-precision stability Belt scale with eight pairs of idlers floating balance scale frame alignment, each group of scales with a free floating balance structure, breaking the traditional design concept, unlimited structure, double load cell Direct force transmission , High precision.

Scale side with PLR-D digital converter, the scene directly to the digital analog device for remote FH-03-type weighing instrument, speed device PLR-12RS type.

Belt Scale-16 Series FH Dynamic cumulative error of 0.10-0.2%, Suitable for A Variety of Weighing Accuracy requirements Type of High Occasions. ESPECIALLY for MAGAZINE at The entry of Thermal Power Generation Measurement, at The Port of loading and unloading Ship Metering, and Steel Plants Other metering between the measurement accuracy requirements of the occasion and a variety of foreign trade settlement.